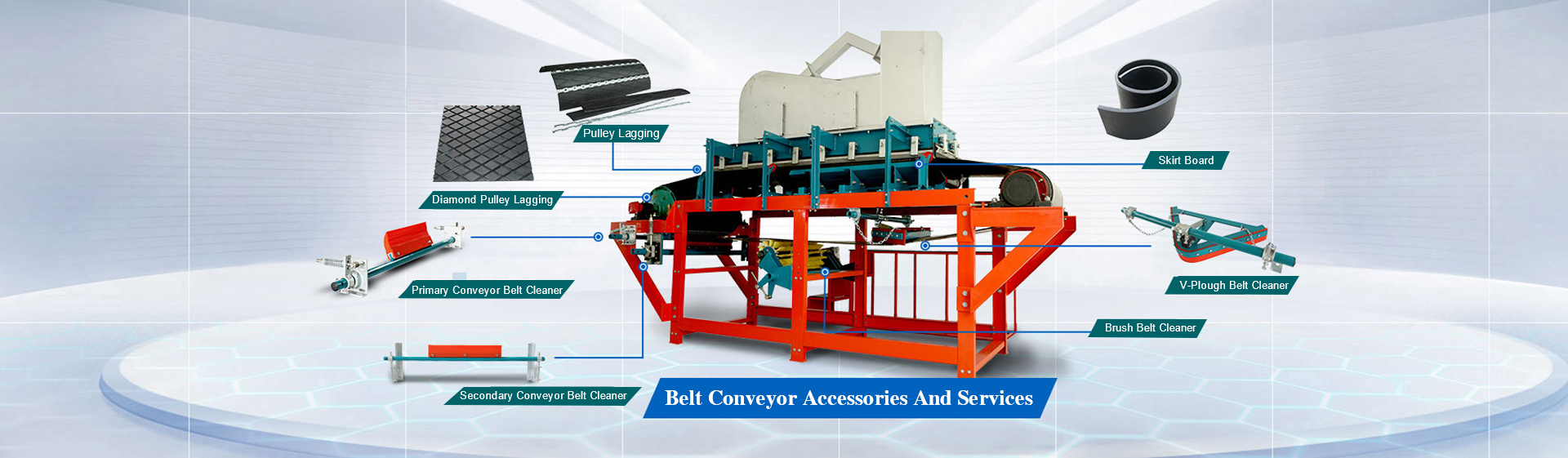

PRODUCTS

Debang ceramic coating

Ceramic Pulley Lagging

●Eliminate belt slippage.

●Improve tracking.

●Extend life of belt and pulley.

●Abrasion resistance and long wear life.

●Reduce downtime and main tenance.

Jiaozuo Debon Technology Co., Ltd.

www.apexmultiservices.com

Email: leila@debonrubber.com

PH:+86 152 2583 7728

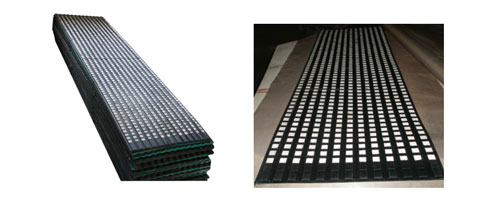

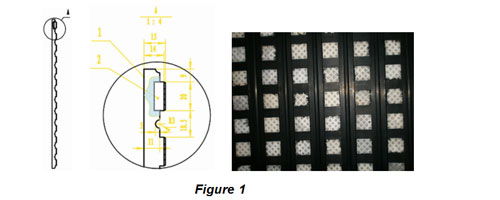

Ceramic Pulley Lagging Sheets Solution For Belt Slippage

Ceramic Pulley Lagging is essential to improve conveyor belt performance.

It is specially suited for pulleys where slippage and excessive wear and tear problems make normal rubber lagging ineffective. The alumina ceramic tiles help in proper grip of the belt under wet, muddy or any other such arduous conditions.

Technical Data:

Ceramic Tile:

1. Al2O3: 95%

2. Ceramic Hardness(Mohs): > 9t

3. Working temperature: -40 - 85℃

Rubber:

1. Material: NR & SBR

2. Hardness: 65 Shore A

3. Density: 1.2± 0.05 g/cm3

4. Tensile strength: min. 15 MPa

5. Elongation at Break: min.450%

6. Wear loss: 80mm3

CN Bonding Layer:

1. Hardness: 70-75 Shore A

2. CN bonding layer to ensure higher bonding strength to pulley surface.

3. Semi-vulcanizing Chloroprene rubber.

Other:

It is suitable for pulleys performing in the most difficult conditions.

Can be installed by cold vulcanization.

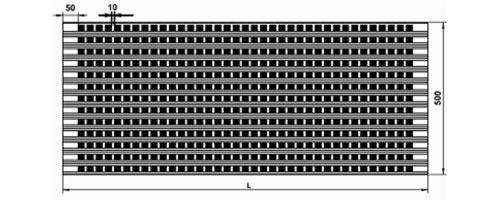

ZE-TC50015 Ceramic Lagging is 15mm thick and 500mm width, length according to customer's pulley length.

See Fig. 1 below.

- Prev:Debang science and technology buffer strip

- Next:No;

-

On-site training. More insight into the applications, more development.

2019-10-19 -

Safety is no small matter. Make safety your first thought and take precautions from tiny things.

2019-10-19 -

What Is Pulley Lagging

2019-10-21 -

Introduction of Pulley Lagging Installation Procedures

2019-10-21 -

Factors Affecting Wear Resistance of Pulley Lagging

2019-10-21 -

Advantages of Pulley Lagging

2019-10-21 -

Introduction of Wear Liners

2019-10-21

-

Significant Features of Wear Resistant Compound Steel Wear Plate

2019-10-21 -

Introduction of Conveyor Skirt Board and How to Install it

2019-10-21 -

Introduction of Belt Cleaner

2019-10-21 -

Features and Types of Belt Cleaners

2019-10-21 -

Introduction of Impact Bed

2019-10-21 -

Advantages of Impact Bed

2019-10-21 -

Design of Impact bed

2019-10-21